The 6th Chapek Prize Award Ceremony will be held in Wuhu soon

The 6th Capek Prize Award Ceremony and the 10th China International Robotics Summit will be held at the Yueyuanfang Hotel in Wuhu, Anhui Province from 27-29 August. The Capek Prize, an award named after Czech science fiction writer Karel Capek, aims to reward organisations and individuals who have contributed to the field of robotics and recognise their contributions to the development of the industry. Academicians and scholars, industry experts such as Cai Hegao, Shan Zhongde, Wang Yaonan, Ding Han, Zhao Jie, Sun Lining, Wang Tianmiao, Qu Daokui, Song Jijiang, as well as many renowned entrepreneurs will be the guests of the 6th Capek Award Ceremony.

Chapec official website

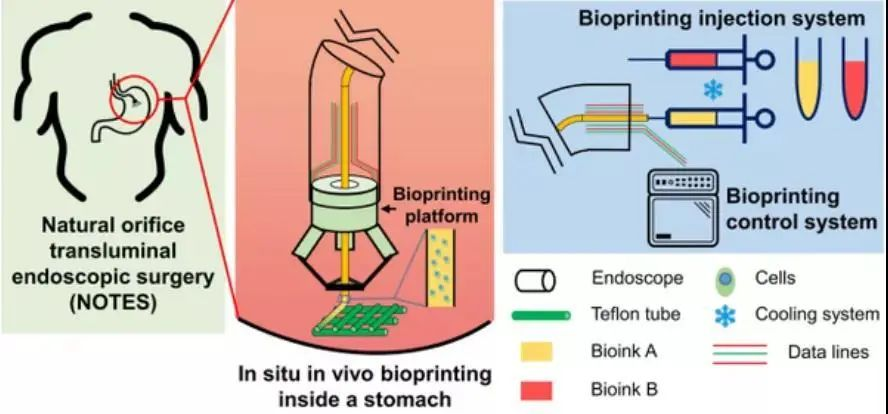

Tsinghua University has developed a snake-shaped bioprinted robot that can enter the body to treat stomach wounds

Recently, Professor Tao Xu of Tsinghua University in China, through collaboration with PhD student Wenxiang Zhao, Tao Xu has developed a prototype snake-shaped robot that can be inserted into a patient’s stomach through an endoscope. The robot’s head consists of a rigid base surrounded by three independently moving arms. During insertion, it folds into a very thin shape and then opens when it reaches the wound site. Once in the target location, its arms extrude a tube and squeeze out two hydrogel bioinks, one containing human gastric epithelial cells and the other containing human gastric smooth muscle cells. These are then deposited on two separate layers to form a scaffold that covers the wound.

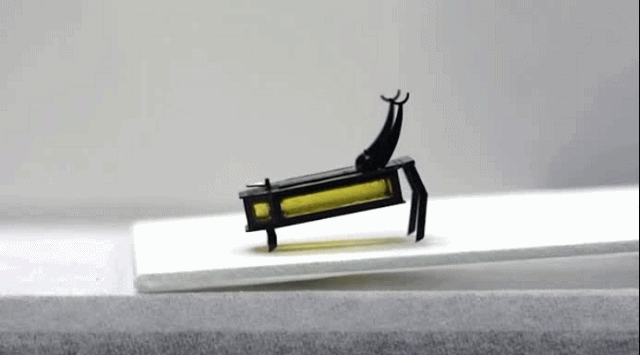

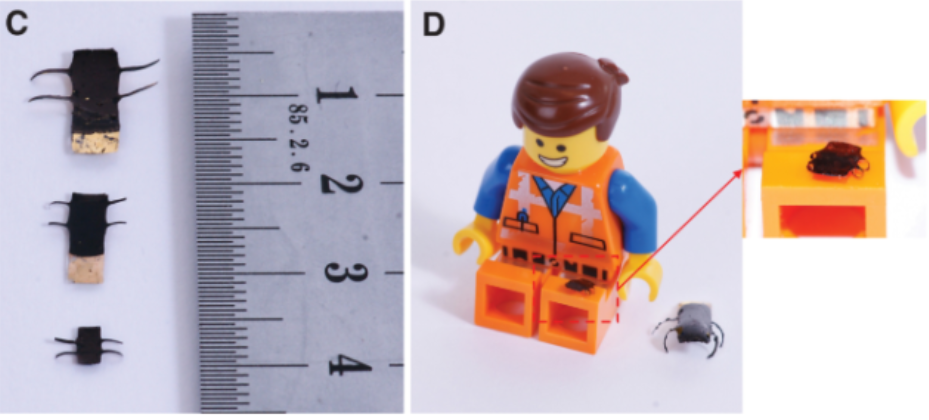

HUST Alumni 88mg Robot on the Cover of Science Sub-Issue

In the latest issue of Science Robotics, a paper describing the “RoBeetle” robot was published. RoBeetle weighs just 88 milligrams and can haul 2.6 times its own weight. It can carry an additional 95 milligrams of fuel and has a range of up to two hours. roBeetle has the ability to climb slopes and travel on surfaces with different textures, including glass, foam sleeping mats, and concrete pavements.

New rechargeable zinc batteries could be integrated into robotic structures to provide more energy

Robots are now able to perform some incredible feats, whether it’s herding sheep in New Zealand or delivering medical supplies in Rwanda, according to foreign media outlet New Atlas. One way they could reach greater heights is if some of their structural materials doubled up as energy storage, much like fat in animals. Scientists have now demonstrated this approach with a multifunctional battery. They estimate that this technology could power future robots up to 72 times their current configuration. The work was carried out by engineers at the University of Michigan who are investigating the potential of cheap, non-toxic zinc batteries to power a new generation of robotic devices. These batteries transport hydroxide ions between the zinc electrode and the air cathode through membranes made from water-based polymer gels and aramid nanofibres used in Kevlar vests, a design that opens up some interesting multifunctionality.

Swedish University Researchers Develop 4D Printed Micron-Scale Soft Robots Based on 3D Printers

A group of researchers at Sweden’s Linköping University have developed a set of microactuators for micro-robotics using extrusion-based 3D printers, according to foreign media reports. The actuators are said to contain an electroactive polymer that changes shape in the presence of an electrical charge after printing, giving them 4D functionality, which in soft robotics is equivalent to muscle contraction. While 4D-printed soft robots are usually limited to the centimetre or millimetre scale, today’s technology researchers have narrowed down their actuation mechanisms to the micrometre range, with a thickness of around 20 microns. They claim their customised machines are versatile and scalable, and hope to “expand the scope of soft robotics” with previously invisible and complex microbots.

4D printing is also a method of 3D printing whereby objects are deformed over time using materials that can be deformed.

US DARPA AlphaDogfight competition ends with AI beating human flight instructors 5:0

The highly anticipated DARPA AlphaDogfight Challenge came to a close on 20 August when Heron Systems’ AI algorithm overwhelmingly defeated a human pilot in a virtual air battle. After three days of intense competition from 18-20 August, Heron Systems was selected as the winner of the DARPA AlphaDogfight Challenge out of seven teams and won 5:0 against a human F16 pilot wearing AR glasses in a VR F16 simulator.