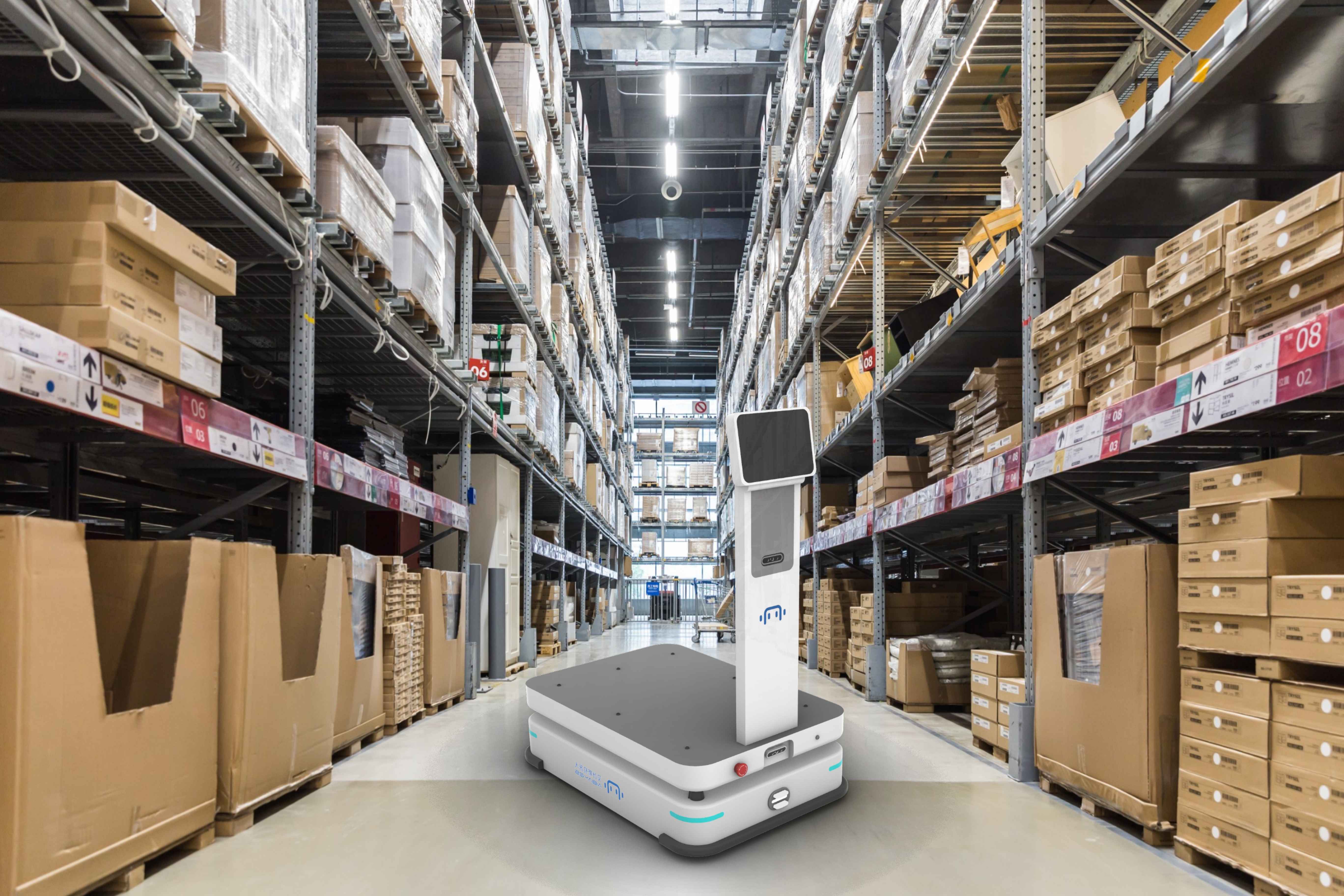

Warehouse automation is the biggest trend in logistics. The latest generation of robots such as Autonomous Mobile Robots (AMR) take flexibility, efficiency and safety to a new level.

The Rise of Warehouse Automation

The complexities of modern supply chains have spurred the adoption of warehouse automation as a pivotal solution. This trend is driven by the need for increased efficiency, accuracy, and adaptability to meet the growing demands of global commerce. Warehouse automation involves the use of cutting-edge technologies to streamline and optimize various processes within a storage facility, with robots playing a central role.

Robots in Action

Robotic applications within warehouses have revolutionized material handling processes. Autonomous Mobile Robots (AMRs) navigate seamlessly through the warehouse environment, carrying out tasks such as picking, packing, and sorting with precision. These robots are equipped with advanced sensors, machine learning algorithms, and robotic arms, enabling them to adapt to dynamic warehouse layouts and efficiently process diverse types of inventories.

Advantages of Robot Integration

The application of robots in warehouse automation brings forth a myriad of advantages. One key benefit is the significant enhancement of operational efficiency. Robots operate 24/7, tirelessly executing tasks without the need for breaks, resulting in a continuous and uninterrupted workflow. This efficiency not only reduces labor costs but also accelerates order fulfillment, ensuring timely delivery to meet customer expectations.

Accuracy is another critical aspect where robots excel. Equipped with advanced sensors and real-time data processing capabilities, robots minimize errors in tasks such as inventory management and order picking. This not only improves overall accuracy but also contributes to a reduction in costly mistakes within the supply chain.

Furthermore, warehouse automation enhances adaptability. Robots can quickly adjust to changes in demand, seasonal fluctuations, or modifications in the warehouse layout. This flexibility is essential for businesses striving to maintain a competitive edge in an ever-changing market.

(Our AMR named FLASH working in the warehouse)

Future Implications

As warehouse automation continues to evolve, its impact on the logistics industry will be transformative. The rise of collaborative robots, capable of working alongside human counterparts, opens up new possibilities for enhanced productivity and creativity. The cooperation between human and robot promises to redefine the roles within logistics, creating a more efficient and harmonious working environment.

In conclusion, warehouse automation, driven by the increasing prevalence of robots, is undeniably the forefront of the logistics industry. As technology continues to advance, the relationship between humans and robots within the warehouse is poised to revolutionize how we perceive and execute logistics. Warehouse automation is not just a trend; it is the future of logistics.

If you would like to learn more about our robotic products and solutions, please feel free to leave a message or call us for consultation. Email is [email protected]. Also, you can add our WhatsApp +86 181 1289 9721.