In recent years, with the continuous advancement of technology, robotics has found its way into various industries, revolutionizing the way tasks are accomplished. One such significant application is the use of logistics AMRs in large warehouses. These highly efficient machines have gained popularity due to their widespread adoption and numerous advantages in streamlining warehouse operations. This article explores the prevalence and advantages of employing logistics robots for material handling in large-scale warehouses.

Universality of Logistics AMR: The application of logistics handling robots has become increasingly prevalent in the logistics and warehousing industry. From e-commerce giants to manufacturing giants, numerous companies have recognized the potential of these machines to optimize their supply chain processes. The automation of repetitive tasks, such as material handling, inventory management, and order fulfillment, has significantly boosted efficiency and productivity in warehouses of all sizes.

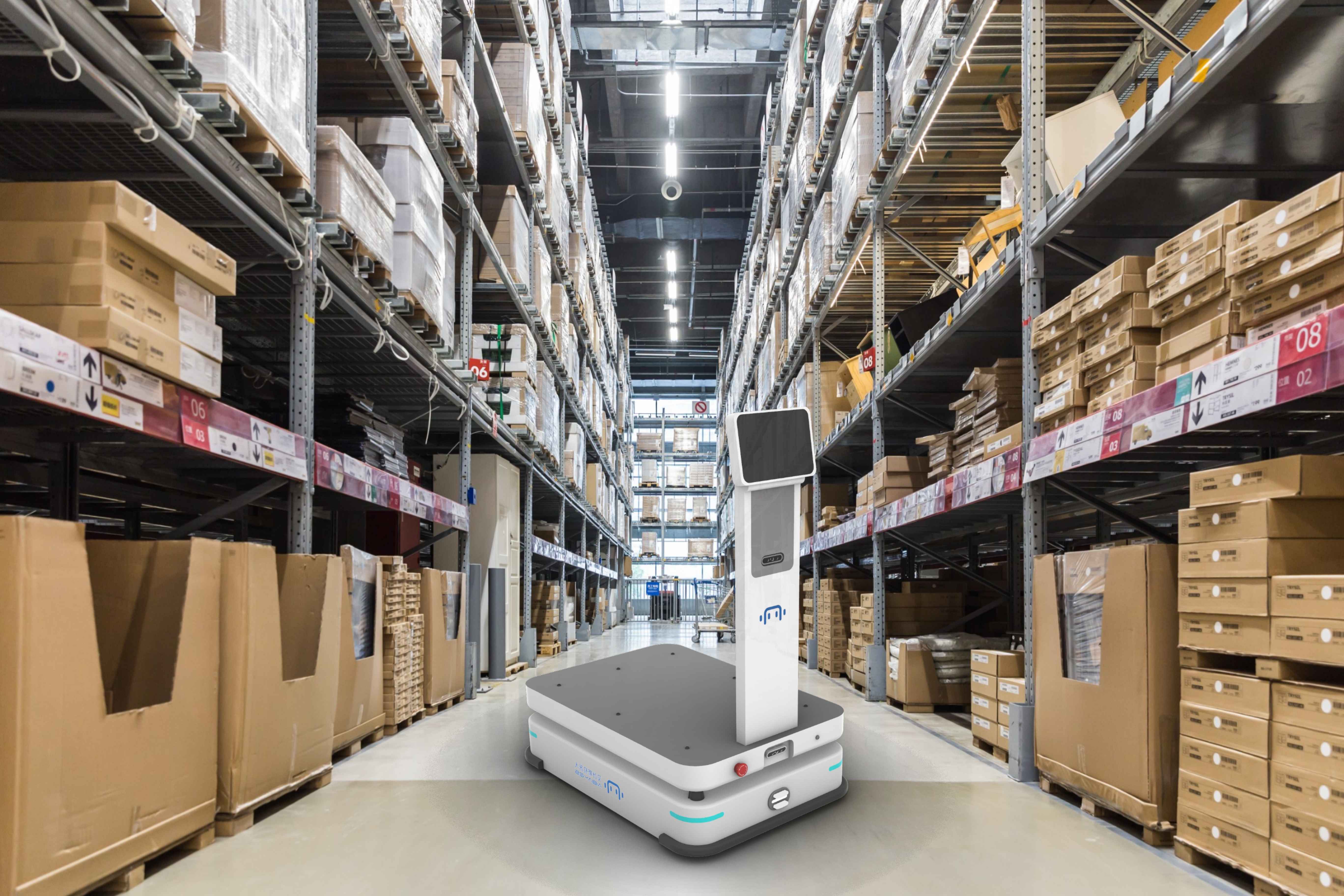

(The picture of our lifting AMR named MAX 600 serving for material handling)

One of the primary advantages of using logistics AMRs in large warehouses is the significant increase in efficiency. These robots are programmed to perform tasks with utmost precision and speed, outperforming human capabilities in terms of speed and consistency. With the ability to work around the clock without fatigue, they ensure a continuous workflow, reducing downtime and enhancing overall warehouse performance.

Besides, large warehouses often deal with heavy and bulky items, posing potential risks to human workers during handling. By deploying robots for these tasks, companies can reduce the risk of accidents and injuries. These machines are equipped with advanced sensors and safety features, ensuring a safe working environment for both robots and human employees. As a result, the overall safety record of the warehouse improves significantly.

Logistics handling robots are designed to navigate through narrow aisles and confined spaces efficiently. Their compact size and advanced navigation systems enable them to make the most out of available warehouse space, maximizing storage capacity and optimizing the layout, realizing optimal space utilization. This results in reduced storage costs and better space utilization overall.

A notable advantage of logistics handling robots is their compatibility with existing warehouse management systems (WMS) and technologies. They can be seamlessly integrated into the warehouse’s digital infrastructure, allowing for real-time data exchange and enhanced control over inventory. This integration facilitates smoother workflows and improves decision-making processes for warehouse managers.

(The picture of our logistics AMR named FLASH 300-L serving for material handling)

Though the initial investment in logistics AMRs may seem substantial, their long-term benefits make them a cost-effective solution. As automation reduces the reliance on manual labor, companies can optimize their workforce and allocate human resources to more complex tasks that require human expertise. Additionally, the reduction in human-related errors minimizes operational losses, ultimately leading to significant cost savings.

The application of logistics robots in large warehouses has become a game-changer in the logistics industry and supply chain industry. The prevalence of these robots is increasing due to their remarkable advantages. From streamlining operations and increasing efficiency to ensuring worker safety and optimizing space utilization, logistics AMRs have proven to be an invaluable asset for any large-scale warehouse. As technology continues to advance, we can expect even more innovations that will further enhance the capabilities of these robots and transform the warehousing industry in the years to come.

If you would like to learn more about our robotic products and solutions, please feel free to leave a message or call us for consultation. Email is [email protected]. Also you can add our WhatsApp +86 181 1289 9721.