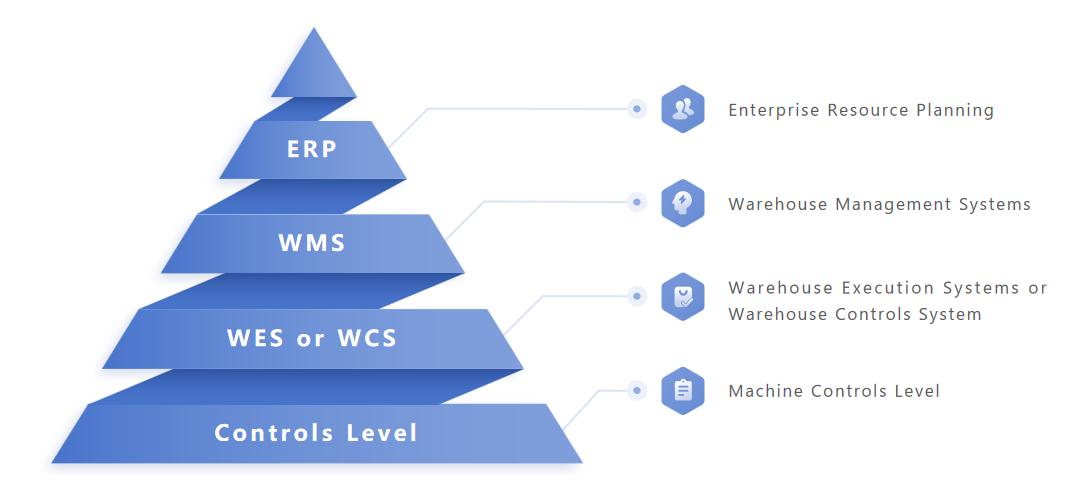

Modern order fulfillment depends on certain software to keep the operation running smoothly and efficiently. For most warehouse centers, this will at a minimum include a warehouse management system (WMS) and an enterprise resource planning (ERP) software. Of course, operations with a large amount of automation will also require software to manage that equipment, typically in the form of either a warehouse execution system (WES) or a warehouse controls system (WCS).

Taken together, these four options—ERP, WMS, WCS, and WES—are the most common types of warehouse software that you are likely to come across and potentially leverage in your operation.

In order to understand how these four systems relate to one another and work together in your operation, just remember this simple rule: The WCS/WES feeds into the WMS, which itself feeds into the ERP.

1.Enterprise Resource Planning (ERP) Software

The enterprise resource planning (ERP) software is essentially an integrated business suite for your operation. It is designed to collect, store, and manage data from across multiple departments within your business. This will often include information about manufacturing, e-commerce, customer relations, sales, marketing, inventory management, shipping, product planning, and more.

The ERP is especially valuable due to the fact that it includes comprehensive financial reporting capabilities that allows you to invoice, bill, track, etc. In addition to the WMS, other systems will feed into it, making it a central repository of data for your entire operation.

2.Warehouse Management System (WMS)

The warehouse management system (WMS) is responsible for the flow of inventory within the warehouse or distribution center. As such, the WMS plays a critical role in, well, managing the activities of the warehouse. Transportation management, supply chain integration, labor management and shipping management all fall under the helm of the WMS, as may some additional functionality.

As mentioned above, the WMS is generally integrated with the ERP. The WCS or WES integrate into the WMS as well.

(Storage Information Query Interface)

3.Warehouse Controls System (WCS)

The warehouse controls system (WCS) is responsible for managing automated technologies in use throughout the warehouse. For example, the activities of your automated storage and retrieval systems (AS/RS), sortation, conveyors, and more will all typically be managed by WCS.

4.Warehouse Execution System (WES)

The easiest way to describe a warehouse execution system (WES) is to say that it is essentially the next generation of the WCS. The resources that the WES truly optimizes is both labor and equipment. The WES applies labor where and when needed and directs automated equipment to assure that all zones and areas within a facility are operating not only at peak but orchestrated.

Regardless of which specific software you are looking to implement within your operation, it’s important that the option you choose is the best one for your particular business needs and goals. With this in mind, we consider modularity, flexibility, and robust functionality to be hallmarks of all top warehouse software, whether you are in the market for an ERP, WMS, WES, or WCS.

If you would like to learn more about our robotic products and solutions, please feel free to leave a message or call us for consultation. Email is [email protected]. Also, you can add our WhatsApp +86 181 1289 9721.