Improving efficiency in a warehouse is a challenge. In most warehouses, things don’t stay still for long, with new stock coming in, deliveries going out and a lot of sorting, packing and picking in between. There are so many moving parts that small delays or mistakes in one area can create knock-on impacts on the whole system. This can make efficiency seem like an unachievable goal, but robotic automation is offering a new solution.

A lot of the challenges are either because of a need for more staff or due to human error. These are perpetual problems, but new solutions are arising every day. One part of the solution to improving warehouse efficiency might be to delegate menial tasks to computers. Robotic Automation is now sophisticated enough that industries can benefit from applying this technology and bringing warehouse efficiency into the twenty-first century.

Ease Labour Shortages

Many in the logistics and warehouse industries are struggling to hire enough people to cover both day-to-day, repetitive tasks and high-level, problem-solving tasks.

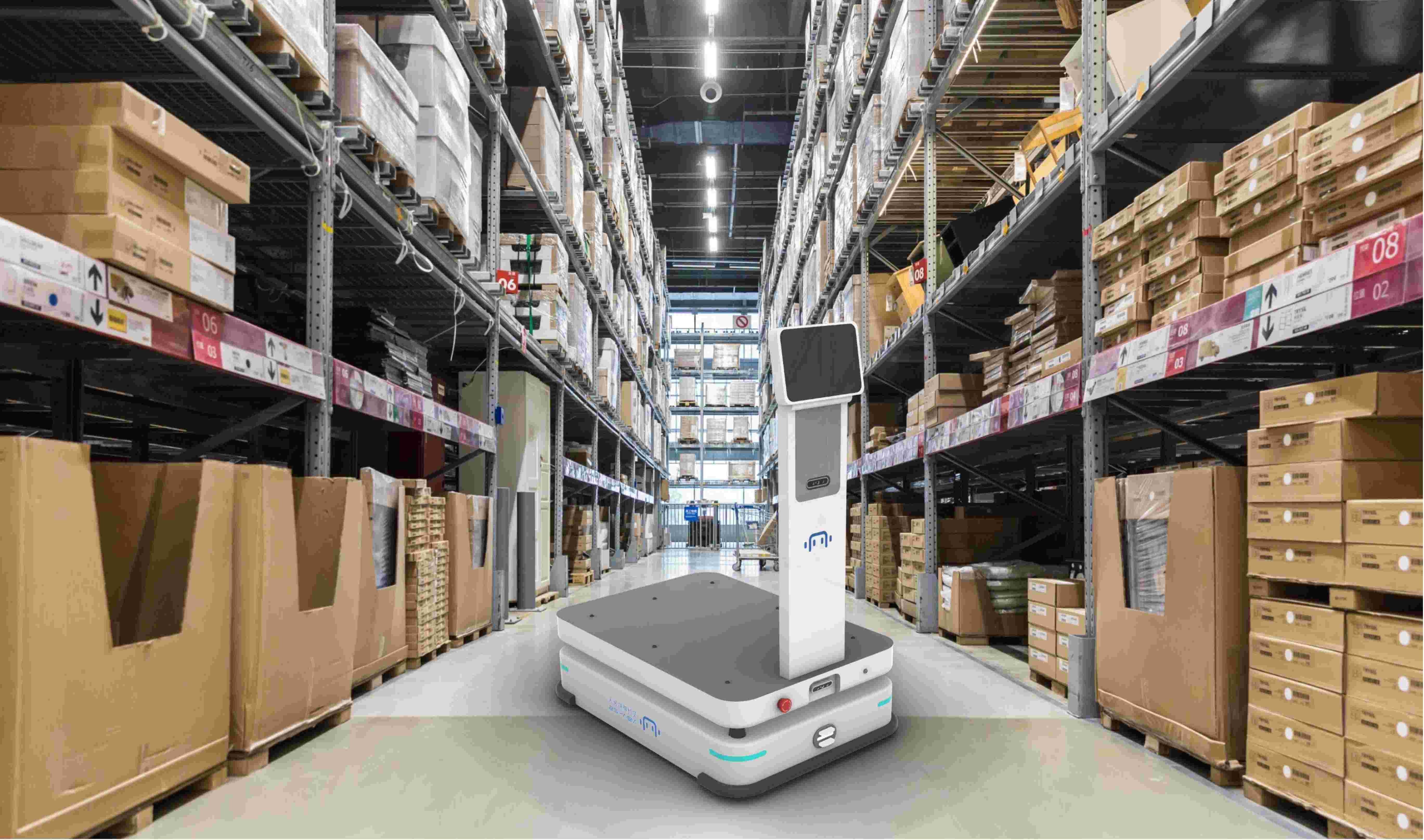

With automation, many small tasks happen without any human action. This can be a scanner reading barcodes as packages come down a conveyor, and a programmer sorting them into different areas automatically. Or it could be an autonomous robot picking and retrieving packages and transporting them to the correct location.

With autonomous mobile robots (AMRs), a warehouse can reduce the time workers spend driving or walking around the facility, freeing them up to focus on more valuable work.

Improve Accuracy

One of the errors that can cause delays in warehouses is inaccuracy. The wrong product is retrieved, or the product is stored in the wrong place.

Put to Light sortation system improves accuracy by guiding operatives to the correct area, using LED lights to illuminate the correct storage location given by a scanned barcode. This type of system is already in use in many warehouses, and AMRs can integrate with it, working alongside existing operations without disruption or reconfiguration.

Reduce Travel Time for Workers and Increase Productivity

The robots can navigate warehouses using their sensors, so they are able to travel to storage locations autonomously. It is able to simply set up the route and move on to other tasks, while the AMR does retrieval tasks and goods transportation. This reduces the amount of time spent walking and searching between warehouse areas for each operative, improving efficiency at work.

(Our AMR named FLASH working in the warehouse)

Warehouse Automation: the Future of Distribution?

We’ve discussed just five ways that automation can improve warehouse efficiency, including helping address labour shortages and improve both safety and accuracy. Other ways include:

- Evaluating Throughput Levels: Because the systems are all computerized, there is a digital monitoring and records system to help understand how the stock is moving.

- Increasing Warehouse Capacity: By using automation and AMRs to transport goods to storage, warehouses can make efficient use of space, compacting goods and using the full height of the facility to expand the total storage capacity.

- Providing Flexibility: Automated solutions are easily scalable. For example, a warehouse might bring in additional AMRs at peak times to cope with demand or run a reduced fleet during slow seasons.

If you would like to learn more about our robotic products and solutions, please feel free to leave a message or call us for consultation. Email is [email protected]. Also, you can add our WhatsApp +86 181 1289 9721.